Every year, millions of people around the world take pills they think are real medicine - but aren’t. Counterfeit drugs don’t just fail to work. They can kill. A single fake antibiotic might contain chalk instead of active ingredients. A counterfeit cancer drug could be laced with toxic chemicals. The World Health Organization estimates 1 in 10 medical products in low- and middle-income countries is fake or substandard. Even in wealthy nations, supply chain gaps make it possible for counterfeiters to slip in fake insulin, heart meds, or COVID treatments. The stakes couldn’t be higher.

What’s Changing in the Fight Against Fake Drugs?

The old methods of fighting counterfeit drugs - visual inspections, paper trails, and basic barcodes - are crumbling. Counterfeiters now use high-resolution printers, AI-generated packaging designs, and stolen serial numbers to replicate even the most trusted brands. But the industry is fighting back with technologies that make forgery nearly impossible.The biggest shift? From batch-level tracking to unit-level serialization. Instead of tracking a box of 1,000 pills as one unit, every single pill bottle or blister pack now has its own unique digital identity. This isn’t just a label. It’s a digital fingerprint tied to the product’s entire journey - from the factory floor to your pharmacy shelf.

The U.S. Drug Supply Chain Security Act (DSCSA) and the EU’s Falsified Medicines Directive (FMD) are forcing this change. By November 2025, every prescription drug sold in the U.S. must be serialized. That means manufacturers, wholesalers, distributors, and pharmacies all have to scan and verify each unit. Failure means fines, recalls, or being shut out of the market.

How Serialization Works - And Why It’s Not Enough Alone

Serialization means assigning a unique code - usually a 2D barcode - to every drug package. That code contains information like the product ID, batch number, expiration date, and a random serial number. When the drug moves through the supply chain, each handler scans it and uploads the data to a secure database.It sounds simple. But here’s the catch: a basic QR code can be copied. In 2025, a major U.S. pharmaceutical company discovered that counterfeiters had replicated their QR codes and sold fake versions to online pharmacies. The result? A $147 million recall. The problem wasn’t the system - it was the lack of cryptographic protection.

That’s why serialization alone isn’t the final answer. It’s the foundation. The real breakthroughs are happening on top of it.

NFC: The Smartphone That Checks Your Medicine

Imagine tapping your phone on a pill bottle and instantly seeing if it’s real. That’s NFC - Near Field Communication - in action. Unlike QR codes, NFC chips store encrypted data that can’t be copied without the original key. They work like contactless credit cards: no app needed, just tap.According to ForgeStop’s 2025 field tests, NFC verification is 37% faster than barcode scanning and reduces false positives by 92%. Pharmacists in Latin America now verify over 1,200 packages a day using nothing but their smartphones. Each check takes 2 seconds. The system also logs the time, location, and device used - creating an audit trail that counterfeiters can’t fake.

For this to work, you need a smartphone. Luckily, 89% of phones shipped in 2025 support NFC. That means almost everyone can verify their medicine with a tap. And because the data is encrypted at the chip level, even if someone photographs the NFC tag, they can’t clone it.

Blockchain: The Unbreakable Ledger

Blockchain isn’t just for cryptocurrency. In pharma, it’s becoming the backbone of trust. Every time a drug is scanned - whether by a warehouse worker, a distributor, or a pharmacist - that event gets recorded on a shared, immutable ledger. No one can delete or alter it.Companies like De Beers used blockchain to track diamonds. Now, pharmaceutical firms are doing the same for insulin vials and chemotherapy drugs. The system doesn’t just track location. It tracks conditions too. If a shipment of vaccines was exposed to heat during transit, the blockchain records the temperature spike. That’s not just about fraud - it’s about safety.

The downside? Integration is slow. Gartner estimates it takes 18 to 24 months to fully connect blockchain systems to existing ERP and WMS platforms. Small manufacturers can’t afford the cost or complexity. But for big pharma, it’s becoming mandatory.

DNA Markers and Forensic Inks: The Invisible Shield

Some of the most advanced anti-counterfeit tech is invisible. DNA-based authentication embeds a synthetic biological code into the packaging or label. It’s like a genetic barcode - unique to each product line. To verify it, you need a handheld reader that analyzes the DNA sequence. Counterfeiters can’t replicate this without access to the original lab.Thermochromic inks change color with heat. UV inks glow under black light. Holograms shift when tilted. These are overt and covert features - meant to be checked by trained staff or patients with simple tools.

But here’s the reality: these features are expensive. DNA markers cost $0.15 to $0.25 per unit. Standard serialization? Just $0.02 to $0.05. That’s why DNA tech is still mostly used for high-value drugs like oncology treatments or rare disease meds.

AI Vision Systems: The Digital Eyeball

At the end of the line - in pharmacies and hospitals - human inspectors are being replaced by AI-powered cameras. These systems scan packaging for tiny inconsistencies: a slightly off font, a misaligned logo, a color shade that’s 2% different.In controlled labs, these systems detect fakes with 99.2% accuracy. In real-world settings? It’s harder. Lighting, packaging reflections, and damaged labels create noise. But accuracy has jumped from 89.7% in 2024 to 94.3% in mid-2025. Companies like Cognitivemarket are now training these systems on thousands of real counterfeit samples - not just theoretical ones.

The goal isn’t to replace humans. It’s to give them a second pair of eyes. A pharmacist can now run a quick scan before handing over a prescription - and get an instant alert if something’s wrong.

What’s Holding Back Wider Adoption?

The tech exists. So why aren’t all drugs protected?Cost is the biggest barrier. A mid-sized manufacturer might spend $2 million to upgrade its packaging line for serialization and NFC. That’s not feasible for companies with thin margins. Many in Asia and Africa still rely on manual checks - and pay the price in counterfeit deaths.

Regulatory delays are another issue. While the U.S. and EU are moving fast, countries like Nigeria and Brazil only rolled out mandatory serialization in early 2025. Many African nations still lack the infrastructure to scan digital codes.

And then there’s the tariff problem. In April 2025, the U.S. imposed new tariffs on pharmaceuticals and packaging materials from China and India - ranging from 10% to 46%. That’s raised production costs by 12-18% and delayed shipments by 3 to 6 weeks. Some manufacturers are cutting corners to compensate - risking quality and security.

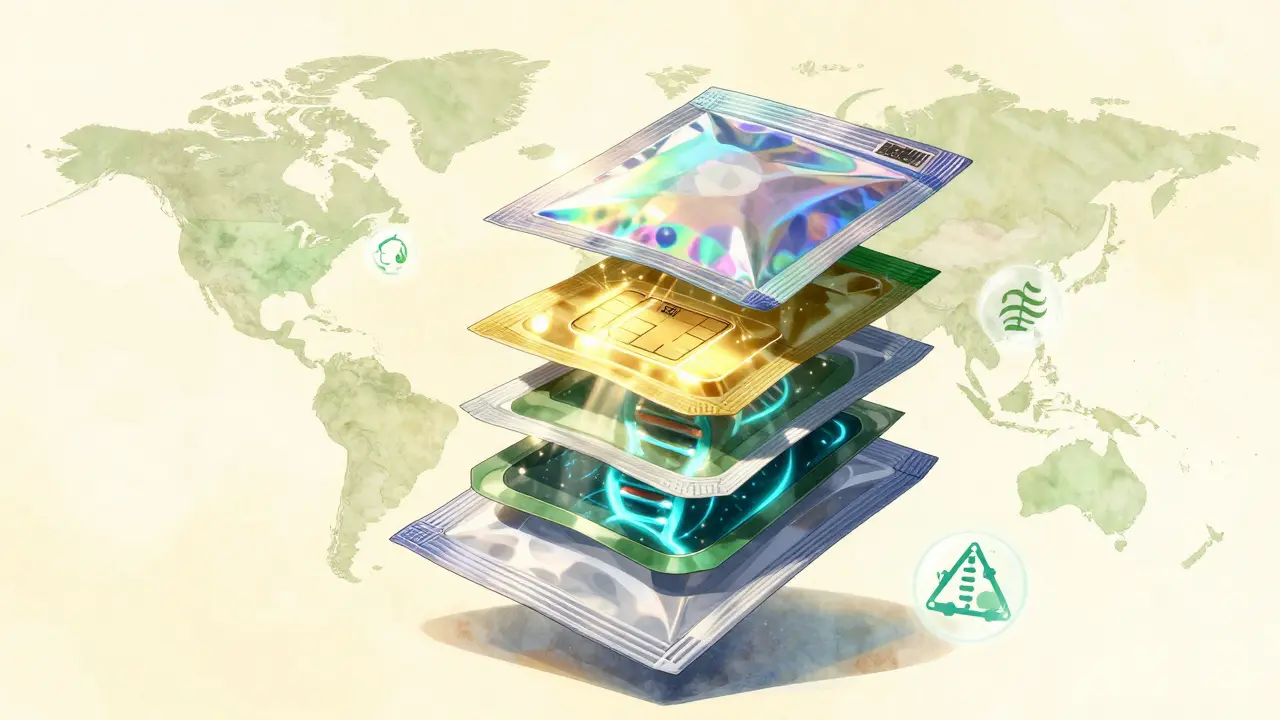

What’s Next? The Future Is Multi-Layered

No single technology will solve this alone. The future is layered security:- A cryptographically secured NFC tag on the pack

- A hologram visible to the naked eye

- A QR code that links to a blockchain record

- A DNA marker detectable only by lab equipment

- An AI scanner at the pharmacy counter

By 2027, 83% of pharmaceutical executives say they’ll use at least three of these layers together. The goal isn’t perfection - it’s making counterfeiting so hard and expensive that it’s not worth the risk.

Even better? Many of these new materials are eco-friendly. Recyclable packaging now embeds traceable markers without adding plastic. Sustainability and security are no longer at odds.

What Should You Do as a Patient?

You don’t need to be a tech expert. But you can protect yourself:- If your pharmacy uses NFC, tap your phone on the package. You’ll get an instant verification.

- Check for tamper-evident seals - broken caps, missing shrink bands, or loose blister packs are red flags.

- Buy from licensed pharmacies only. Avoid websites that sell pills without a prescription.

- If a drug looks, tastes, or feels different - talk to your pharmacist. Report it.

Counterfeit drugs thrive in silence. Your awareness is part of the solution.

Will This End Fake Drugs Forever?

No. Criminals will adapt. AI is already being used to generate fake packaging that fools basic scanners. But the game has changed. What used to take a weekend to fake now takes months, millions in R&D, and access to proprietary systems.Today’s technologies don’t just detect fakes - they make them obsolete. The next time you pick up a prescription, you won’t just trust the label. You’ll know it’s real - because the system is built to prove it.

13 Comments

Henry Ip

January 16, 2026 AT 06:11This is huge. I never realized how easy it is for fake meds to slip through. NFC taps are already saving lives in some clinics. We just need to make this standard everywhere, not just for fancy drugs.

Cheryl Griffith

January 17, 2026 AT 08:51I work in a pharmacy and we just got the new AI scanners. It’s wild how they catch stuff humans miss. Like a logo that’s 0.5mm off or a font that’s slightly thinner. I used to just trust the label. Now I actually check.

Bobbi-Marie Nova

January 17, 2026 AT 22:12So we’re spending millions to stop people from buying fake Viagra on Instagram but still letting unregulated supplements fly under the radar? Classic.

Rob Deneke

January 18, 2026 AT 14:42Blockchain is cool but most small pharmacies cant afford it. Serialization alone is better than nothing. We need to start with what works not what sounds fancy

evelyn wellding

January 20, 2026 AT 09:56OMG I just tapped my insulin bottle with my phone and it said REAL!! 😭 This tech is actually giving me hope. My grandma almost died from fake blood pressure pills last year. Thank you to everyone making this happen 🙏

Chelsea Harton

January 21, 2026 AT 09:32DNA markers are overkill. Like why not just use QR codes and call it a day. We dont need to genetically engineer our pill bottles

Corey Chrisinger

January 23, 2026 AT 09:19It’s funny how we build these complex systems to prove something is real… but we still live in a world where people trust a random website because the logo looks legit. Technology can’t fix gullibility.

Bianca Leonhardt

January 24, 2026 AT 11:14Of course this works in the US and EU. In Nigeria? People are still buying pills off street vendors with no idea what’s inside. All this tech is just a luxury for rich countries. The rest of the world is just waiting to die.

Travis Craw

January 25, 2026 AT 12:35I get that this is important but the tariffs on packaging from Asia are making this way harder than it needs to be. We’re punishing manufacturers for something they didn’t do. Maybe fix the trade policy first?

Christina Bilotti

January 27, 2026 AT 07:24Wow. So we’ve moved from ‘trust your doctor’ to ‘tap your phone to verify your medicine’? How quaint. I suppose next we’ll need a biometric handshake before taking aspirin. The paranoia has officially peaked.

brooke wright

January 28, 2026 AT 21:20Wait so if I tap my phone on my pill bottle and it says real… does that mean the pill actually works? Or just that the packaging is legit? Because I’ve taken real pills that did nothing. Just saying.

Nick Cole

January 30, 2026 AT 12:23The real win here isn’t the tech. It’s that patients are finally being given tools to protect themselves. That shift from passive recipient to active verifier? That’s the real revolution.

Jody Fahrenkrug

January 31, 2026 AT 00:52I just hope they don’t make the verification app paywalled. Imagine having to pay $5 a month to know your blood pressure meds aren’t chalk.